Enertech Electro-Hydraulic Operator (EHO)

Enertech Electro-Hydraulic Operator (EHO)

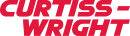

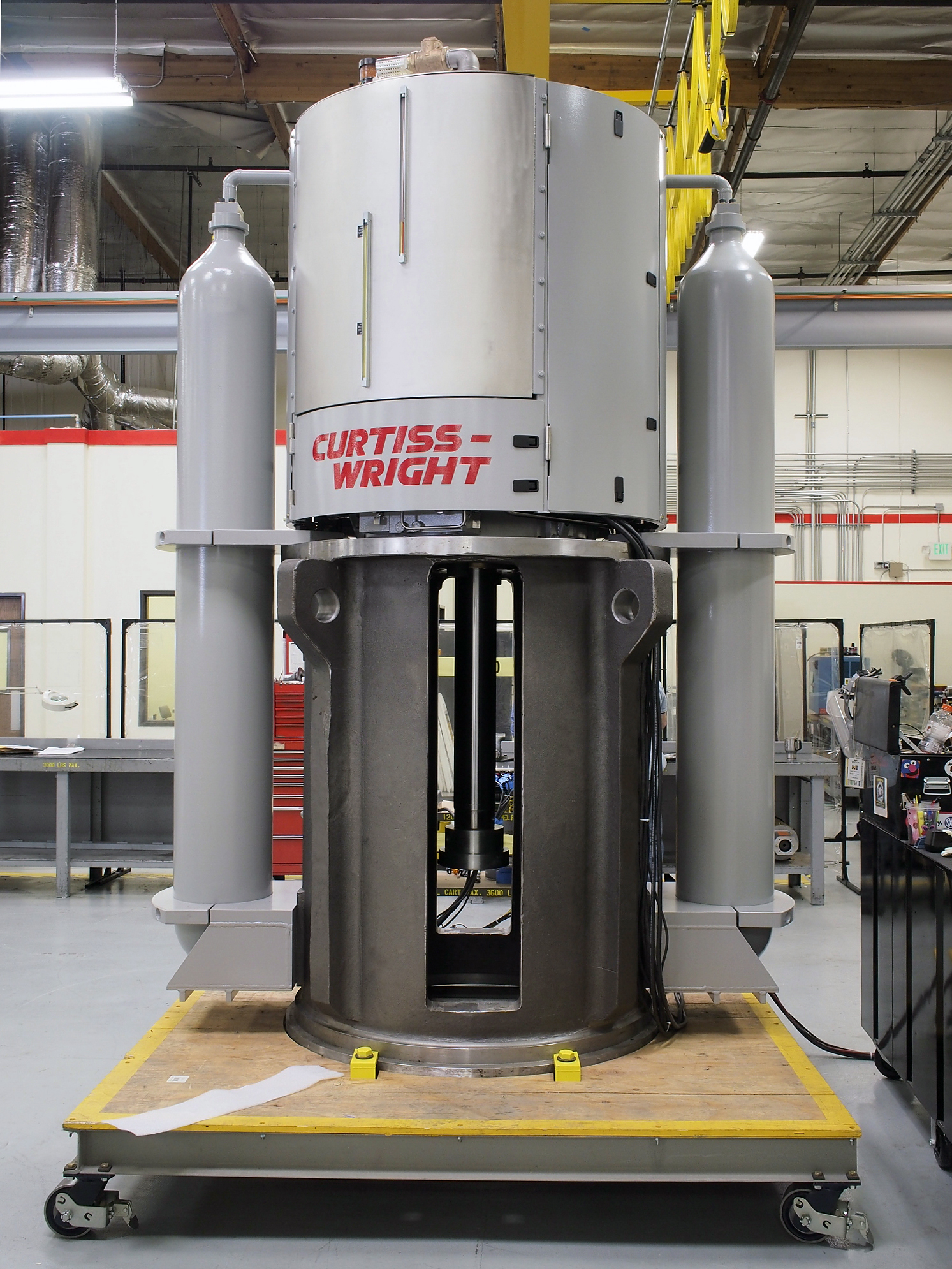

Developed in 1976, the Enertech Electro-Hydraulic Operator (EHO) supports the needs of emergency and safety systems found in commercial nuclear power plants. These actuators are especially suited for applications requiring quick closing or opening valves where the torque/thrust exceeds the capabilities of typical pneumatic and motor actuators. Enertech EHO's are commonly used in critical applications such as Main Steam and Feedwater Isolation.

Compact, yet robust in design, the Enertech Electro-Hydraulic Operator eliminates the need for backup power. The linear and rotary actuators have been IEEE qualified to 323, 344, 382 for inside and outside containment. With multiple installations worldwide the Enertech EHO has been the solution to some of the nuclear power industry’s most demanding applications.

.

.

Key Features and Benefits

| Optimum Deadband | Less than 2% of input |

| Ideal Input Linearity | Less than 2% of ideal total input span |

| Adjustable Stroking Speed | Up to 10 in/sec or adjustable |

Principles of Operation

Enertech EHOs rely on several key components working together. The Hydraulic Cylinder delivers consistent, reliable thrust with its heavy-duty design. The Reservoir stores hydraulic fluid, supplying pumps to maintain pressure and ensure the operator is ready when needed. Pressure Switches monitor pressure in the cylinder, while Solenoid-Operated Valves control fluid flow—directing it to the cylinder for opening and releasing it for rapid closing. Hydraulic Pumps regulates system pressure by cycling on and off based on signals from the pressure switches. Finally, Gas Bottles store pressurized gas energy, ensuring the motive force needed for valve isolation or cycling.

In the event of an accident or loss of power, the EHO's stored energy can be used to return the valve to its safe or normal position, or even provide limited operation. The Enertech EHO provides maximum thrust or torque for critical safety applications.

General Specifications

| Design: |

|

| Materials of Construction: |

|

| Environmental Ratings: |

|

| Typical Ratings: | Up to a total of 192 megarads (100 megarads Normal and 92 megarads Accident) |

| Cycle Life: | 5,000 (linear) and 10,000 (modulating) |

| Normal Conditions: | 131°F & 100% relative humidity |

| Accident Conditions: | 395°F, 66 psig, 100% relative humidity and chemical coolant spray |

| Hydraulic Fluid: | Fyrquel® 220 or Synquench 620 FRH |

| Control Signal: | 4-20 mA (250 ohms resistant) increasing signal open valve |

| Power Supply: | 460 VAC, 3 PH, 60Hz |

Typical Plant Applications

Curtiss-Wright Electro-Hydraulic Operators (EHO) support PWR, BWR, and CANDU reactors. Our EHOs are commonly used to operate:

- Main Steam Isolation Valves (MSIV)

- Main Feedwater Isolation Valves (MFIV)

- HVAC Dampers

- Containment Isolation Valves

- Main Steam Atmospheric Dump Valves (MSADV or PORV)

- Recirculation Flow Control Valves

- Any valve requiring high thrust or stored energy

To request for more information click here